Lean 6 Sigma

As of the end of 2016, 3300 projects, in which a total of 2900 Borusan employees participated, have been completed within the Borusan Group and these projects have provided Borusan with a value of USD 150 million.

As of the end of 2016, 3300 projects, in which a total of 2900 Borusan employees participated, have been completed within the Borusan Group and these projects have provided Borusan with a value of USD 150 million.

Lean 6 Sigma

6 Sigma in the Borusan Group

6 Sigma is a modern business methodology that is applied by the world’s giant companies and aims to continuously increase the productivity, profitability and customer satisfaction in business and production processes.

The system, whose basic principles were developed by Motorola in 1986, has benefited from methodologies such as Quality Control, Total Quality Control and Zero Error, as well as the teaching of pioneers such as Shewhart, Deming, Juran, Ishikawa and Taguchi. The system was first put to use by Motorola, Honeywell and GE.

The Borusan Group has been using this methodology since 2002.

Thanks to the 6 Sigma methodology, which constitutes an important pillar of Borusan’s strategic management model, Borusan’s companies both increase their financial growth and profitability, as well as affecting a change of culture.

The 6 Sigma studies are run by full-time employees, Black Belts specializing in methodology, supervising projects and providing training projects, as well as by Master Green Belts on a half-time basis and Borusan employees at all levels.

As of 2016, 3300 projects have been completed with the participation of a total of 2900 Borusan employees and these projects have provided Borusan with a value of USD 150 million.

You can visit www.yalin6sigma.com for Lean 6 Sigma Training Programs and Consultancy Services.

What is Lean 6 Sigma?

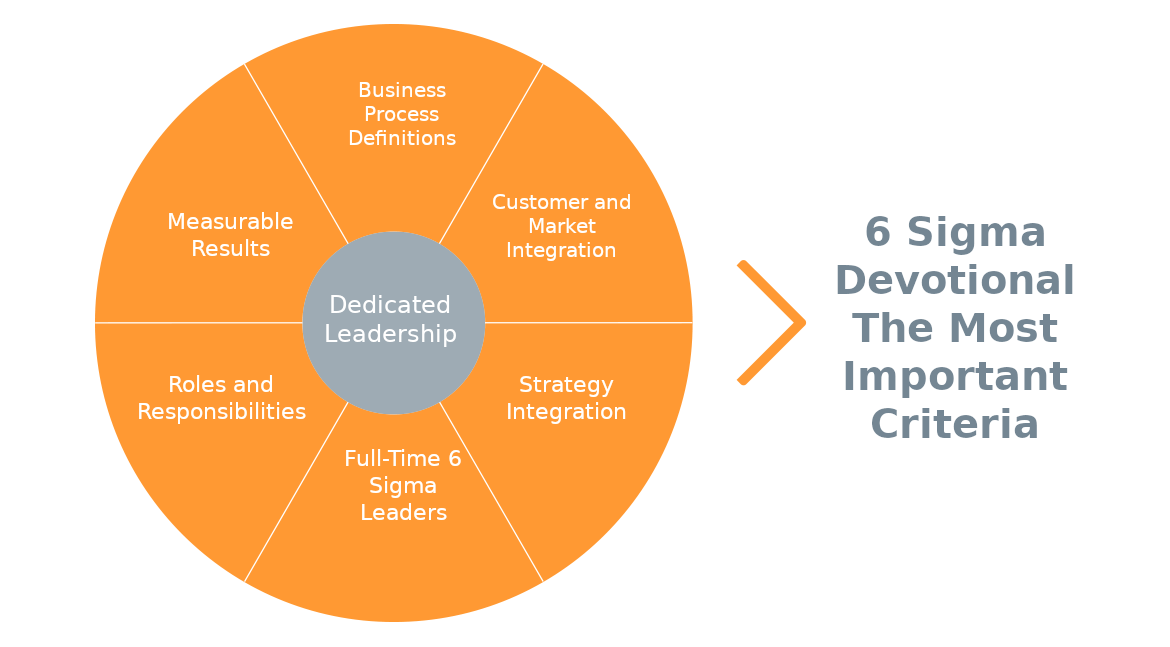

Lean 6 Sigma is a way of managing a project with defined steps and goals:

Through continuous and decisive leadership support

Through increasing the quality of process output by locating and removing error sources

Through using a specific human resource infrastructure that is focused on this work in the organization

Through using quality management and statistical tools

There are basically two types of projects in the 6 Sigma methodology.

DMAIC studies cover the improvement of existing products or processes.

DMEDI projects include the development of new products and services.

Lean 6 Sigma at Borusan Lojistik

Our mission as a Borusan Lojistik Lean 6 Sigma organization;

“To spread the principle of data-based work across the company as a whole to enable the company to adopt processes that will provide the highest customer satisfaction and profitability with minimum resources.”

Our lean 6 Sigma success factors in the realization of this mission;

Lean 6 Sigma at Borusan Lojistik in Numbers

As of 2016;

Number of Black Belts: 4

Number of Active Master Green Belts: 122

Number of those in the Lean 6 Sigma Group: 701

Number of Black Belt Projects (cumulative) : 132

Number of Master Green Belt Projects (cumulative) : 175